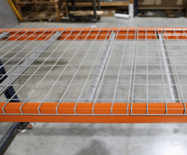

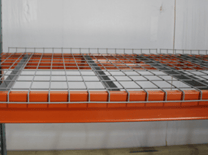

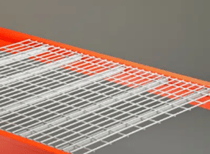

Wire mesh decking is designed to be placed on the horizontal beams of pallet racks to provide support for palletized loads and improve the overall functionality of the storage system. It consists of a grid or mesh pattern made from steel wires which keeps loose products from falling through the racks and potentially hitting workers on the floor below. Furthermore, wire mesh decking can aid forklift drivers align pallets into their storage position before placing them on the beams.

To guarantee its safety, warehouses should only use wire mesh decking that has been created following the ANSI MH26.2: Design Fabrication code. According to the standard, the client must provide the rack’s dimensions information and load capacity rating to the wire mesh decking manufacturer prior to design and construction. Because the wire decking load calculations differ from the other storage rack components, sharing that information assures that the decking will fit the system and that the deck capacity meets its intended application.

There are different varieties of wire mesh decking that are typically available:

- Waterfall: Wire mesh decking that extends over the edge of the supporting beams, resembling a waterfall. The term “waterfall” describes how the wire mesh is configured on the edges of the decking.

- Flat Flush: Wire mesh decking that sits directly on the beam steps.

- Straight (Falt): Wire mesh decking that spans the entire beam span.

There is no standard that requires these fall-restraint devices to be attached to the racks, but...

Design codes ask that safety bars be fixed to the beams (front and back) because they can move from side to side. However, there is no clear recommendation in the codes for wire mesh decking. We know that although waterfall-type wire mesh will not laterally move and cannot simply fall off the rack, it is better to attach them to beams as they sometimes get lifted by pallets during operation.

There are various best practices to maintain the safety and integrity of the accessory, in addition to only employing wire mesh decking that has been built and produced to meet a specific racking application:

- Ensure that the wire mesh is installed according to manufacturer specifications and guidelines.

- Be aware of the load capacity of the wire mesh and ensure that it is not exceeded.

- Conduct regular inspections of the wire mesh to identify any signs of damage, corrosion, or wear. If the wire mesh racks are in an environment prone to corrosion, consider applying protective coatings or using corrosion-resistant materials.

- Inspect if the wire mesh is still properly placed on the beams and that the load is uniformly distributed over the decking. Overloading can lead to structural damage and compromise safety.

References

Pallet Rack Now. (2022, April 8). Wire Decking: Everything You Need to Know. Retrieved from palletracknow: https://palletracknow.com/wire-decking-everything-you-need-to-know/

Rack and Shelf. (2023). rackandshelf. Retrieved from Flat Wire Decking for Boltless Shelving: https://rackandshelf.com/product/storage-products/warehouse-racks/pallet-rack-decking/flat-wire-decking-for-boltless-shelving-2/

Rackandshelf. (2023). PALLET RACK DECKING. Retrieved from rackandshelf.com: https://rackandshelf.com/c/storage-products/warehouse-racks/pallet-rack-decking/