Adopting a safety-focused mindset is an excellent start to addressing rack safety in your warehouse. But with so many products available on the market, knowing which safety devices to use can be challenging.

Choosing the wrong component could make things worse than using no protection at all. By the end of this article, you will have a better understanding of the products available to make your warehouse and racks safer.

Protecting Your Warehouse: Key Components to Consider

A warehouse can be a very active space. Workers and forklifts are busy loading and unloading material in the racks. A pallet of goods can quickly move through the facility and be gone the next day. Because of these dynamics and the inherent risks of warehousing activities, it's wise to outfit areas prone to damage with safety devices.

At its most basic, a warehouse or distribution center receives merchandise, stores it on racking systems, and eventually uses it internally or ships it out again.

There are three main things to protect: the people, the stored goods, and the building assets, which include, of course, the storage systems and the building itself. We can, therefore, split protection devices into these categories.

“To increase the safety of your warehouse, protect people, products, and storage systems.”

Protection for People and Products in Your Warehouse

A variety of fall-protection and containment products, such as safety netting, space guards, and wire mesh panels, can help keep employees safe from falling objects and prevent product loss.

Building Column Protectors

These warehouse column protectors are intended to safeguard the structural columns that support the building’s roof.

They come in a variety of materials and shapes. The strap-and-ratchet systems are made of plastic, high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), or vinyl. They wrap around the columns to absorb shock from material handling equipment. Heavy-duty steel products, round or square, are a solid barrier against lift trucks’ high impacts.

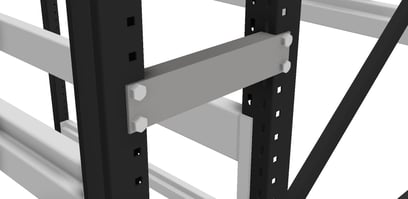

Safety Bars

Safety bars prevent misplaced pallets from falling through or prevent beams from spreading apart, especially structural beams.

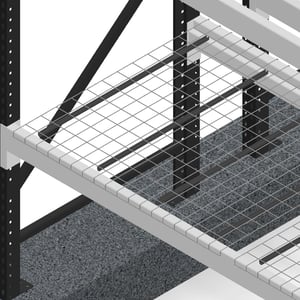

Rack Decking

As the name suggests, these safety devices sit atop the two beams in a cell, provide a surface deck, and prevent smaller packages from falling through. They are often recommended on the first level of a tunnel bay.

Rack decking can be used in conjunction with safety bars, most of the time being of the welded-wire decking variety. Other common types are made of bent sheet metal or corrugated steel with holes punched out of it to meet the National Fire Protection Association’s (NFPA) 50% minimum exposed area for water flow in case of a fire.

Safety Netting

Vertical warehouse containment netting or pallet rack netting provides an effective barrier for keeping loose items or cartons from falling into a workspace or aisle way, protecting anyone walking by storage racks and offering product fall protection. It can be made from various materials like fabric, plastic, or wire mesh, and can also be fire-retardant. Safety netting can be easily installed on the racking frames. They are a smart investment, especially in warehouses that deal with small packages or loose palletized material.

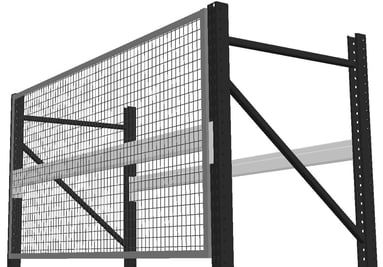

Wire Mesh Backers and Space Guards

Made from welded wire mesh with a frame of L-channel or flat bar steel, these panels bolt directly to the racking system’s frames. Like safety netting, rack space guards help protect pedestrian walkways and adjacent work zones from falling materials while maintaining visibility and ventilation.

Flue Protection

For fire safety, it is important to maintain an empty space between back-to-back rack systems. Flue spaces are openings within the pallet rack structure that allow vertical lines of sight stemming from the floor up to the ceiling.

An open flue space provides for heat and smoke to rise in the event of a fire. If fire suppression sprinklers are triggered, the open flue space also allows for the water to penetrate the multiple levels of stored product to extinguish the fire at its source. A blocked flue space directs the fire horizontally, allowing it to increase in size and intensity, increasing damage and loss.

Flue Protection Devices: The Importance of Proper Pallet Stoppers

Flue protection devices, or pallet stoppers, are products that limit pallet movement within a cell so that the open area around it can be safely respected.

The International Building Code (IBC2012) requires 6" of longitudinal open flue space and 3-4" of transverse clearance between merchandise and pallet rack uprights. Pallet stoppers come in all shapes and sizes. Your goal is to choose a style that leaves the most open flue space.

Protection for Racking System Structures

Rack Upright Guards

This safety device protects a pallet rack system’s upright column by shielding it with steel, plastic, or elastomer rubber. They come in various shapes and sizes. Some are fastened to the ground at a short distance from the column, while others are directly installed on the column for added rigidity.

Material selection and anchoring will dictate the energy absorption rate. A plastic or elastomer column guard will more gradually absorb energy and eventually cause column deformation.

These styles tend not to be bolted to the ground. They also occupy more space as material thickness is required for energy absorption.

Steel guards have more immediate energy absorption as they tend to be anchored and made of thick steel. Those with a low-profile and fitted form are appreciated by those who do not want guarding solutions to protrude into the aisles.

End of Aisle Protection

This protection device is installed at the end of a rack aisle to prevent impacts on the part of the system that is prone to damage from forklifts, especially on the corners. They are generally placed at the base of the rack and measure roughly 12-24" in height. More heavy-duty guardrails or fences can also be used in critical areas with high forklift traffic. These are made of different materials, chiefly plastic or steel; however, both styles are anchored to the ground at a short distance from the upright frame.

Guard Rails

These protection devices, much like those you see on highways, act as fences or bumpers to protect machinery, walkways, in-plant offices, personnel, inventory, and equipment from damage or injury. In many cases, these can be seen delimiting areas of racking or travel lanes to separate forklifts from foot traffic. They are made of steel, plastic, or rubber to absorb impact.

Guide Rails

Unlike guard rails, guide rails are used near or within the rack aisles at floor level, to help “guide” forklifts down an aisle in selective racking systems. They are commonly used for drive-in and drive-through applications, where forklifts move into the rack, where a slight misalignment could cause severe damage to the structure.

Bollards

Just like guard rails, bollards are static structures, used to protect racking systems, office spaces, or building walls near loading areas, both indoors and outdoors. They usually take the shape of a cylinder and are roughly 3 to 4 feet in height. Bollards can also be made of steel or plastic, and sold hollow, or installed and filled with concrete for added stopping power. They are bolted directly to the ground.

Key Takeaways: Choosing the Right Rack Safety Products for Your Warehouse

Now that you have a better idea of the types of safety protection devices at your disposal, it may still be a little overwhelming to process all this information and know how to move forward in making your warehouse a safer environment. Simply remembering that in any warehouse, you need to protect three main things: the merchandise, your building (including rack structures), and most importantly, your employees.

Partnering with a knowledgeable rack safety solutions provider is strongly suggested, as they will offer their guidance to help you along the way. Damotech’s large scope of expertise in everything related to rack safety can assist in isolating issues and help prevent recurrence. We also manufacture a variety of protection and repair products, which have been stress-tested to meet demands, helping to make your choice even easier.

FAQ: Rack Safety Products and Warehouse Protection

What are the most essential rack safety products every warehouse should have?

What’s the difference between safety netting and wire mesh backers (space guards)?

Both serve the same purpose—preventing items from falling from pallet racks—but differ in durability.

- Safety netting is flexible and best suited for lightweight cartons or loose products.

- Wire mesh backers (also called rack space guards) are made of steel mesh and provide a rigid barrier, ideal for heavier or irregular loads.

ANSI MH16.1 recognizes both as effective fall-protection accessories when properly installed.

Do I need to install wire mesh decking or safety bars on every beam level?

How do pallet stoppers help with fire safety?

When should I use end-of-aisle protection or guardrails?

How do I decide between steel and plastic protection products?

- Steel guards offer the highest impact resistance and are recommended in heavy-traffic areas.

- Plastic or rubber guards provide gradual energy absorption and are useful where lighter, more flexible protection is needed.

Both types can meet ANSI MH16.1 and RMI design recommendations when properly anchored and tested.

How often should rack safety devices be inspected?

Who can help me assess which rack protection products my facility needs?

Are rack safety products required by OSHA?

What’s the best first step to improve rack safety in my warehouse?