Quebec

(Translated from French by Damotech)

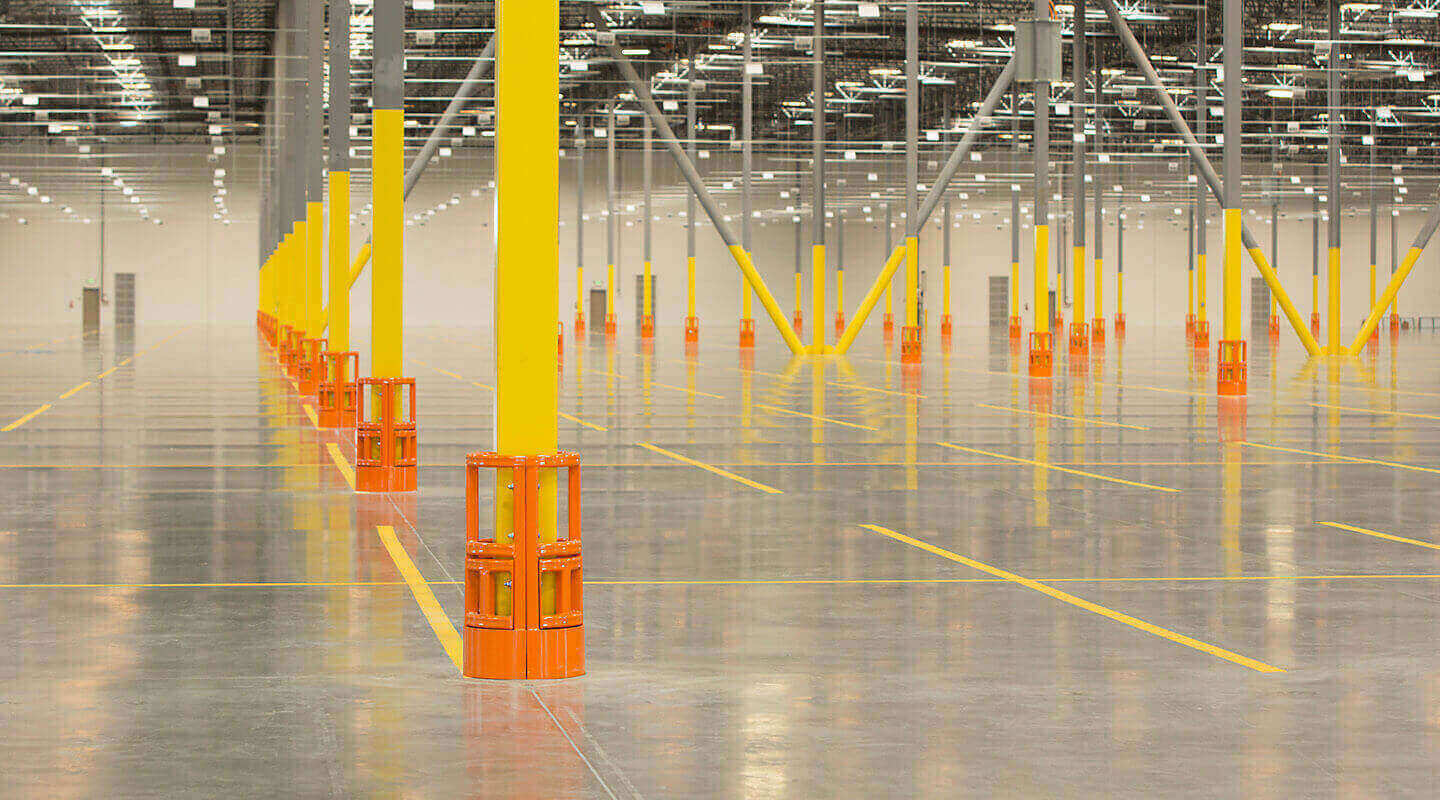

In recent years, Damotech has positioned itself as North America's true leader in pallet rack protection and repair. Thanks to its two lines of rack repair products, the DAMO PRO and the DAMO FLEX, and its unique repair process that does not require unloading, Damotech has become the de facto standard in the rack repair industry. This innovative manufacturing company prides itself on serving every city of more than one million people in North America. Among its customers, no less than 175 companies from the Fortune 500. Damotech has made orange its distinctive brand signature, and most of its products are painted that color. Damotech plans to add its orange-colored products to as many warehouses in North America as possible in the coming years.

The pallet racking company operates three main business divisions: its rack protection and rack repair products, a market that it dominates across North America, its rack engineering and inspection services, and finally its rack inspection software that helps customers optimize and secure their warehouse facilities.

"Damotech manufactures rack protection and rack repair products for warehouses where racks have already been installed," explains President Eric Naaman. But we also have protective products that can be integrated into any new installation to prevent damage before it happens, and consequently, protect our clients' warehouse and rack investments. The company was founded more than 30 years ago by welder Danny Dion, who repaired damaged pallet racking. It is he who, with the help of Robert Bouchard, Damotech's current operations manager, developed Damotech's unique installation process that replaces damaged uprights with stronger units that are better suited to today's busy warehouses. The process has evolved over the years, which has led to the DAMO PRO we use today."

Damotech's unique and highly effective approach allows repairs to be made without unloading of racks, in most cases. "This is definitely a very interesting added value for the customer," says Naaman. "In addition, we offer a lifetime warranty on repairs using the DAMO PRO repair kit. Our products are designed to withstand vertical and horizontal forces, making them not only resistant to the heavy loads, but also to side impact from forklift trucks."

Damotech's target audience consists of small, single-warehouse companies to large multinationals with high production volumes and hundreds to thousands of warehouses. "These are health and safety conscious companies that want to make sure they follow best practices," says Derek Zakaib, CMO at Damotech. "These companies understand the value of having a safe racking system in their warehouses; they work to reduce the risk of incidents to its maximum. In a market like the United States, where lawsuits are common, safe facilities are a top priority for conscientious management."

In 2010, Eric Naaman acquired Damotech with an American partner, from whom he bought back the shares last year. As a commercial photographer for nearly 20 years, Mr. Naaman knows the importance of branding in business. That's why he paid close attention to a multitude of details when designing the new factory in Boisbriand, which impresses everyone who visits. "Our factory, which has LEED certification, is our calling card, a reflection of our brand and values," he explains. "It is for this reason that our factory is so well kept! We invite our customers and prospects to visit our facility so that they can see for themselves our attention to detail at all levels. "

Between 2010 and 2018, Damotech has grown steadily, from 17 to more than 50 employees. "I run my business according to my values," says the president. For me, collaboration and surpassing oneself is essential. We share great synergy because the right people are in the right places. Growth is motivating for all; it stimulates commitment and commitment to the future of the company. I am concerned about offering my employees a work environment that is conducive to their growth. We have put forward a very appreciated employee recognition program, and we promote a style of participative management where we work in complementarity, open to new ideas. "

For the next few years, Damotech intends to continue consolidating its positioning throughout North America. Also, the engineering services and the software platform will be the subject of sustained development. "With orange in every warehouse in North America, we will become a must," says Eric Naaman. Our business decisions are made with this goal in mind. "

Magazine Québec Entreprise, Volume 55

Special Report

By Mélanie Larouche

Original version (in French)