Whether you supervise a single warehouse or operate multiple distribution centers, we aim to help you manage one of your most critical assets: your racking systems. Through our pallet rack inspection & audit services, performed by experienced engineers, we offer you a comprehensive overview of the condition of your racking systems. The detailed reporting, based on rigorous observations by our rack engineers, allows you to take corrective actions and bring your racking back to conformity. The Damotech Platform offers online access to reports with dashboards to help you track your progress and improve safety.

Damotech's in-house engineers are among the most knowledgeable in the industry. They offer expert services on warehouse racking systems and their safety. Learn more about our annual rack compliance audits, load capacity calculations, and warehouse safety trainings.

In the U.S., OSHA law stipulates that company management is responsible for providing a safe workplace to their employees. Canadian jurisdictions also follow the same guidelines. Putting workers at risk of injury can expose employers to serious liability in case of an accident.

Despite the demands of your daily operations, your racking systems must maintain their full integrity over time. Our annual pallet rack inspection services are thorough and always performed by engineers, to certify that your racking systems comply with the local rack design and safety standards.

Our engineers walk through your facility and meticulously inspect your racking systems for compliance, collecting on-site information, taking photos, and recording any deficiencies, damage, or missing components. Our pallet rack inspection services are non-disruptive to your daily operations. Following our visit, we'll issue a detailed report with recommendations.

Regardless of your industry, the type of pallet racks you use, or the damage found in your warehouse, we have the expertise and solutions to help you diagnose, report, and address deficiencies.

There is no precise regulation on the frequency of inspections. It should vary based on the velocity of your operations or the speed at which rack-related issues arise in your warehouse. Generally, most experts and governing bodies such as OSHA agree to recommend yearly independent inspections performed by third-party rack experts or engineers. Monthly assessments by warehouse personnel using software like the Damotech Platform are also recommended.

A thorough third-party inspection is highly recommended before an OSHA audit. A Damotech inspection report will provide your business with an accurate assessment of the condition of your warehouse pallet racking systems (proper installation, unsafe modifications, hazardous damage, or unposted load capacities) and allow necessary measures to be taken to address issues before OSHA visits.

IMPORTANT NOTICE: If your warehouse does not comply with OSHA regulations, you could be fined or forced to temporarily suspend your operations.

New Rack Installation

Whether it's your entire warehouse or a small section, a brand-new installation calls for a 3rd party to verify that everything was installed according to engineering specifications and that the rack systems are ready to be put to safe use.

Corporate Safety Initiative

When launching a corporate-wide safety program, you want a baseline inspection performed to assess the condition of the racks at a specific point in time, and to be able to measure your progress towards a safer warehouse environment.

Timely Re-Assessment

An annual, quarterly, or monthly re-inspection of your racks after a baseline inspection has already been conducted. New damage may have occurred. Updating the status of previously reported issues will give a more accurate measure of performance.

Regulatory Compliance Review

Some jurisdictions require an official document stating that racks have been rated, inspected and are safe to use. Ontario requires a PSR (Pre-start Health and Safety Review) signed by an engineer and British Columbia (WorkSafeBC) also requires inspections.

Repair or Replacement

If your damaged rack was fixed with parts from the original equipment manufacturer (OEM) or a specialized rack repair kit, you may want to ensure that the rack still meets original specifications and maintains its rated load capacity.

Reconfiguration Review

You changed the layout of your racking systems or changed the height of certain beams? An inspection or certification (LARCS) is required by code before putting the rack systems back into usage.

Collapse or Earthquake

Was there a major incident in your warehouse? Whether it was induced by human error like a forklift accident or from a natural cause like an earthquake, you will need to make sure the integrity of your racks have not been compromised.

Regulatory Audit

Before or after a regulatory or corporate audit, you may need a comprehensive report on the conformity of your pallet rack systems or a document that certifies this. Such a report can be produced promptly after a visit by a rack expert.

Pre-Purchase / Change of Tenant

If you are looking to acquire or lease a warehouse and need to know the current condition of the pallet racks inside the warehouse. This should allow to evaluate the investments involved to bring the racking to conformity if necessary.

Performance Benchmarking

Want to make sure your internal inspections are uniform and up-to-par across one or all of your facilities? Let a 3rd party come in and inspect your racks. Compare the reports, then make an informed decision on appropriate next steps.

Operations & Safety Optimization

If you need insight on how to increase rack safety and optimize your racks' performance, our engineers can help. They have the know-how to provide expert advice on how to optimize the efficiency of your warehouse operations while keeping the work environment safe for workers.

Incomplete Documentation

Having up-to-date layouts with associated load capacities is required. Load capacity labels or plaques are also required to be displayed at all times on or near the rack systems to inform warehouse workers of their rated capacity.

Damotech engineers will produce a detailed and actionable inspection report.

It includes:

In the United States and Canada, there are well-defined standards for the safe use of pallet racks in all warehouses. However, sorting through all the different rack safety standards and regulations can be challenging.

In the United States, there are guidelines and regulations from organizations like RMI (Rack Manufacturer's Institute), ANSI (American National Standards Institute), and OSHA (Occupational Safety and Health Administration). Also, there are those established by Canadian government bodies like WorkSafeBC, MOL (Ontario Ministry of Labor), and CSA (Canadian Standards Association).

At Damotech, we have all the required expertise to help you make the entire regulatory audit and certification process as straightforward as possible. So whether you want a PSR review, an OSHA Audit, or an engineer-stamped drawing with load capacities for local/municipal permits, Damotech has you covered.

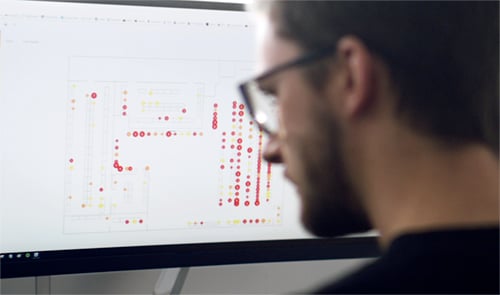

The Damotech Platform is an online software that gives our customers instant access to their warehouses' most recent inspection data. The dashboard shares insightful statistics about inspected racking systems. As reported issues are addressed, customers can track their progress toward achieving their goal of a safer warehouse.

Customers access a visual warehouse layout with all the recorded data for each rack location. They can view, filter, and sort data by current status or damage priority level and the photos taken by the Damotech inspectors. By registering for the Premium Version, users can record new issues themselves, or even perform their own routine assessments.

0

Fortune 500 Clients

0

MSq. Ft. Inspected

0

MHours of Downtime Saved

0

%Warranty Replacements

250

Fortune 500 Clients

500

MSq. Ft. Inspected

Hours of Downtime Saved

Warranty Replacements

Detailed Inspection Reports

Our reports are the most detailed in the industry. All reports contain scope, procedure, key findings, found issues, photos and much more.

Professional Engineers

All our reports are stamped by engineers that are extensively trained by Damotech's professional instructors.

Seismic Expertise

Inspections and calculations take into consideration the site location and seismic effects on the racks.

Reports in 30 Days

Inspection reports are typically delivered within 30 days of P.O. reception.

Anywhere in North America

Our engineers cover Canada and the U.S., including Puerto Rico, Hawaii, Alaska and everywhere in between.

Most Trusted Inspectors

Top performing large (and small) corporations trust Damotech's professionals with the safety of their rack systems.

There is no clear regulation on the frequency of racking inspections. It often depends on the speed at which rack-related issues accumulate in your warehouse. Although not clearly expressed, most governing bodies like OSHA and MOL recommend yearly independent inspections by a third party and monthly assessments by warehouse personnel.

For more detailed info, read our knowledge base article: How often should warehouse racking be inspected?

In the U.S., the IBC (International Building Code) refers to ANSI / MH16.1 (RMI Rack Design Standard) which defines how racks must be designed and maintained. In Canada, the latest NBC (National Building Code) refers to CSA S16 for the design of steel structures, including racks. As this is a relatively new code, some provinces still use the previous rack design code A344.2.

All Damotech inspectors have a bachelor’s degree in engineering. To be certified by Damotech, they undergo a rigorous training program at our facility with an experienced instructor and must then spend a set number of hours visiting warehouse facilities with a Damotech certified inspector.

If severe issues are identified through Damotech's inspection services, our inspectors will notify the main contact at your facility of the immediate actions required.

If your own staff detects severe damage, it is crucial to take immediate action to prevent injuries or further damage. The affected racking systems should be cordoned off. If unloading can be performed safely, you should do so.

Next, contact Damotech to assess and address the damage adequately. We will evaluate the extent of the damage and recommend adequate solutions such as repair or replacement.

In many cases, damaged columns and struts can be effectively repaired using Damotech repair kits. Rack repair is often more cost-effective, less time-consuming and disruptive to your operations than replacing components with OEM parts. The repair process involves using a lifting jack to remove the damaged portion and installing a repair kit. Damotech-engineered rack repair kits restore the full load capacity of your racks and prevent most future damage to the same location.

Yes, but our inspectors do not immediately specify repair solutions as they remain completely independent of the sales process. If you request it, a Damotech representative will gladly help you determine the best solutions to address the reported issues, whether repairing with engineered kits or replacing damaged components with OEM parts.

Damotech rack safety inspections can identify various types of damage or issues in your pallet rack systems. Below is an overview of some more commonly identified issues by component:

Contact one of our rack safety experts for more details on Damotech Rack Inspections.

During a compliance audit, Damotech's engineers walk your entire facility and visually inspect all the racking systems. They look for damaged rack components such as columns, beams, and braces. They also search for missing anchors, safety pins, safety bars, and more. An engineer stamps the report and provides recommendations for bringing the systems back to conformity.

It’s not that we want to skirt around the subject of pricing. We like to know what things cost, too. Our racking inspection services are made-to-measure, and tailored to your specific needs. We inspect facilities large and small, anywhere in North America. Consequently, our pricing will factor geographic location, warehouse size, number of bays, type of environment (dry vs. cold storage) to offer you a detailed quote containing no surprises. Requesting Premium Access to the Damotech Platform will also affects pricing.

Request pricing or call 1 (877) 990-3266 and let us demonstrate the value of the engineering inspection services we provide.

Introducing the Rack Safety Flywheel by Damotech! With over 35 years of industry experience, we've condensed our wealth of knowledge into this powerful tool designed to keep your warehouse operations running smoothly and securely. Our Flywheel breaks down safety principles into easy-to-follow courses of action, giving you the peace of mind of a comprehensive safety program.

Discover the Rack Safety Flywheel