An earthquake can generate stress and cause damage to your pallet racking systems. Before cleaning the aisles from products that have fallen from the racks, you may need to evaluate if the racks are still in good condition and capable of supporting subsequent aftershocks. We've outlined some typical damage that may indicate an earthquake has weakened the racking systems. Here are 5 signs indicating you should call in an expert.

Earthquake waves produce strong lateral motion in both horizontal directions. As a result, in the cross-aisle direction, the braces and columns receive additional compression and tension forces. In the down-aisle direction, base plates and beam-to-column connections resist the horizontal forces. A post-earthquake inspection will, therefore, focus on the key lateral-force-resisting items of the rack systems.

Pulled anchors

Cross-aisle and down-aisle lateral movements of the racks may cause the rack column base plates to flex and partially pull the wedge anchors from the concrete slab. You may notice loose anchors here and there due to normal operation, but if multiple rack columns have this issue, this could be a sign that the anchors were pulled by strong seismic forces acting on the rack system. Carefully watch for cracked concrete around the base plates before hammering and tightening the anchors back into position.

Cross-aisle and down-aisle lateral movements of the racks may cause the rack column base plates to flex and partially pull the wedge anchors from the concrete slab. You may notice loose anchors here and there due to normal operation, but if multiple rack columns have this issue, this could be a sign that the anchors were pulled by strong seismic forces acting on the rack system. Carefully watch for cracked concrete around the base plates before hammering and tightening the anchors back into position.

Out-of-plumb upright frames

Rack uprights are allowed to lean ½” over 10 ft height of out-of-plumb and out-of-straight. Quickly check the upright's verticality with a regular bubble level applied on the front and side of each rack upright. Use a plumb bob or a self-leveling laser if you wish to be more precise. Seal-off racks that are of concern and beyond tolerance.

Deformed or unclipped beam connectors

Carefully check the beam connectors. If you consistently see cracks in the paint, deformed columns or deformed beam clips, the system has been overstressed and should be put out of use until a racking specialist or engineer can inspect it.

Carefully check the beam connectors. If you consistently see cracks in the paint, deformed columns or deformed beam clips, the system has been overstressed and should be put out of use until a racking specialist or engineer can inspect it.

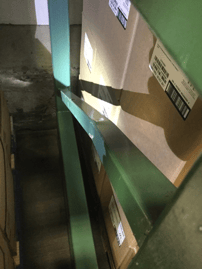

Deformed bracing components

If any of the first 4 bottom upright braces are bent throughout a system, it has been significantly overstressed and should be unloaded and sealed-off.

Cracked welds and joints

Check all rack column base plates for cracks in the welds. Immediately unload pallets on either side of that upright when this issue is found. On welded uprights, check the welds between braces and column lips. The onset of a crack may look like a thin black line in the paint. Also, check if the lips of the column were slightly deformed, pulled or pushed into the column by the brace. Pay special attention to welds between beams and beam clips.

Although rack design codes in North America take into account the effects of probable earthquake-induced forces, warehouse racks should be inspected for signs of overstress if an earthquake has provoked lateral movement. City regulations in Colorado and California, for example, already require an assessment of the racks by an engineer post-earthquake before operating the racks again. Best to check your local regulations for recommendations today, to be prepared when an earthquake occurs.