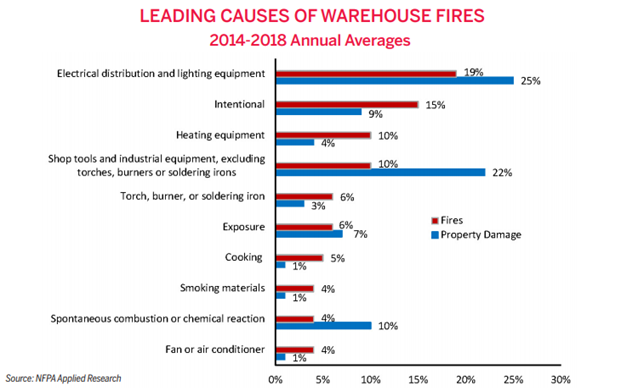

A warehouse fire is not as uncommon as you might think. According to the National Fire Protection Association (NFPA), an average of 1410 warehouse fires a year were reported in the United States between 2014-2018, which equates to about 3-4 warehouse fires a day. This means while you are reading this, a warehouse is dealing with a fire that can potentially cause warehouse damages, injuries, and even loss of life.

Leading Causes of Warehouse Fires

|

| Figure 1. Leading causes of warehouse fires (2014-2018). |

The Invention of Fire Sprinkler Systems

Thanks to the invention of sprinkler systems, most warehouse fires are put out safely. Sprinklers have become one of the most effective ways to reduce the potential for damage and loss of life in a warehouse fire. Luckily, the NFPA provides codes and standards used in over 50 countries, including the USA and Canada, to help facilitate the proper use of sprinklers. When you think about fire safety, it’s important to consider how your racking configuration can also impact the design and implementation of a sprinkler system.

How Do Fire Sprinklers Work?

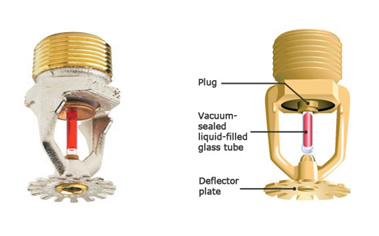

Sprinklers work the same way as faucets in your home, the difference being that heat causes the water to flow from the sprinkler head. A sprinkler consists of a heat-sensitive glass bulb filled with a glycerin-based liquid that expands when heated. The glass bulb is designed to shatter when it reaches a specified temperature. The plug is released once the glass bulb is shattered, and the water begins pouring down onto the deflector. Directly beneath every sprinkler, you will see a flower-shaped metal device called a deflector. The deflector distributes the water in a specific pattern based on the direction the water needs to be dispersed.

|

| Figure 2. Sprinkler photo and diagram. |

Using Warehouse Storage Commodity Classification in Sprinkler System Design

The first step in figuring out your warehouse's sprinkler design is determining the commodity classification of what is being stored. Commodities can be classified between Class I-IV, or Plastics A, B, or C. Plastics have a separate classification due to the high temperatures and speeds at which they burn. Classifying a commodity incorrectly is a very expensive mistake that can lead to an ineffective sprinkler system that cannot control a fire.

The following questions are an important starting point in understanding your commodity classification:

- What materials or chemicals are the stored products made of?

- What type of packaging/container will the products be placed in?

- Will the products be wrapped in plastic?

- What type of pallet is being used (wood or plastic)?

In-Rack Fire Sprinkler System Design Requirements and Limitations

Several factors must be considered when integrating a sprinkler system into your racking. The most common sprinkler systems in a warehouse are ceiling and in-rack sprinklers. In some cases, only ceiling sprinklers will suffice due to their larger orifice, which releases much bigger water droplets to penetrate the fire deeper than traditional sprinklers. However, ceiling sprinklers must be combined with in-rack sprinklers if flue space requirements are unmet.

|

| Figure 3. In-rack fire sprinkler system |

|

| Figure 4. Ceiling fire sprinkler system |

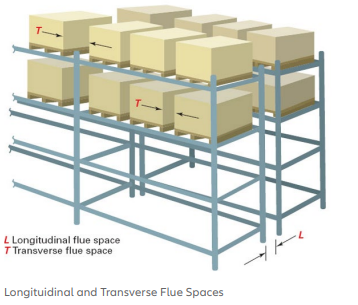

Warehouse Fire Sprinkler Design for Flue Space

The NFPA defines flue space as the clear vertical floor-to-ceiling openings within rack storage areas. Flue spaces are vital in fire protection since they allow the heat to ventilate upward and activate a ceiling sprinkler system much quicker, allowing water to penetrate down throughout the racking system. Not having sufficient flue space can increase the chances of your fire growing horizontally, placing your entire racking system and everything stored directly in the line of fire.

There are two types of flue spaces:

- Transverse: The space between pallets and between pallets and uprights within each row that run parallel to the loading direction.

- Longitudinal: The space between rows of racks.

|

| Figure 5. Flue space |

Depending on your specific Authority Having Jurisdiction (AHJ), you must follow specific flue space requirements as building codes vary from place to place. Ideally, flue spaces should be approximately 6 inches wide, depending on the storage height and the type of racking configuration. To learn more about appropriate clearances, refer to our blog about recommended clearances in warehouses.

When Are In-Rack Sprinklers Required?

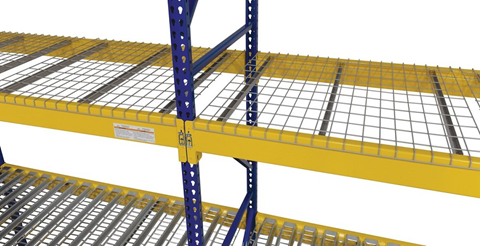

The need for in-rack fire sprinklers comes when the water penetration from the ceiling sprinklers is impeded from getting to the fire anywhere in the system. One solution to consider is to change any solid shelving you might have in your warehouse with wire decking to allow ceiling sprinklers to reach lower levels.

|

| Figure 6. Waterfall wire decking |

The following factors will determine if you need an in-rack sprinkler system:

- Types of commodity classification throughout your warehouse

- Storage and ceiling height of your warehouse

- Width and location of flue spaces in your racking configuration

- Presence of solid shelves

- Having an adequate water supply

If your warehouse has had changes affecting these factors, the effectiveness of the fire protection system may be affected. The building owner is responsible for identifying where these changes have occurred and informing a fire safety professional so that the fire protection system can be re-evaluated.

Considerations and Requirements For In-Rack Fire Sprinklers

Sprinkler design requirements come from a robust set of fire test data that has set the standard of how we should be positioning in-rack sprinklers. Here are a couple of tips to position them properly:

- Ensure that the in-rack sprinkler and piping are arranged to protect from mechanical damage caused by a potential forklift accident. While ensuring that the sprinklers are protected, it is still vital that the sprinklers are in a location where the water can be discharged as intended. To learn more about common forklift accidents in the warehouse, read this.

- Wherever in-rack sprinklers are needed, ensure the deflector is positioned at or just below the bottom of a horizontal brace member.

- Avoid placing sprinkler heads directly behind rack uprights and ensure no more than a 3-inch horizontal offset from the transverse flue space.

Seismic Considerations for In-Rack Fire Sprinkler Systems

If located in a seismic region, ensure sufficient clearance and protection from the piping and racking components to prevent any damage caused by a seismic event. To ensure the lifespan of a sprinkler system, it is important to follow proper seismic design guidance using the most recent edition of NFPA 13.

Seismic Clearances for Fire Sprinklers

NFPA 13 details the exact clearances needed depending on the nominal diameter of the piping used:

- If the pipe diameter is between 1 and 3.5 inches, then a clearance of 2 inches must be provided.

- If the diameter of a pipe is 4 inches or larger, a clearance of 4 inches is required.

Are Warehouse Fire Sprinklers Worth the Trouble?

Fire protection can significantly improve the safety of your building and its inhabitants if you follow the regulations and requirements that apply to your specific region. Some might believe that following these guidelines could cost more money or be too difficult for them to keep up with, but it’s simply not worth gambling with the lives of all those who work inside your facility. According to the NFPA, sprinklers should be inspected annually from the floor level.

Help Following Rack Safety Protocols

Therefore, as a responsible business owner, you should never overlook certain safety protocols. You can start by having your racks assessed by an engineer at Damotech. The engineer can identify if your rack configuration is causing any fire protection issues while also providing the necessary solutions to ensure compliance with regulations and standards by the appropriate authority having jurisdiction. Also, our Damotech-engineered rack repair kits provide a seamless and cheaper alternative to replacing damaged racks because there is no need to reposition or dismantle your in-rack sprinkler system.

References:

NFPA, (2020) Warehouse Fire Safety Fact Sheet. Retrieved from https://www.nfpa.org/