What Is a Safety Pin?

When you think of a safety pin, the first thing that may come to mind is a pin commonly used for securing clothing material together or for earrings. A safety pin in pallet racking has a similar role of acting as extra security. Whether you refer to them as racking safety pins, locking pins, beam locking devices, safety clips, or j-pins, their purpose is to secure pallet rack beams to uprights, preventing the beam from disconnecting when struck with an upward force caused by a pallet load or forklift component.

The Need for Safety Pins

Static pallet racking systems commonly allow very heavy loads of 2,500 lb per pallet. That is 5,000 lb for a pair of beams, roughly equivalent to supporting a pickup truck! You may find it surprising that many rack designs have beams hooked directly into columns. They are held solely by gravity, and the weight of the supported load pushes them down on them, with nothing else preventing the beam from being lifted out of place. With this design, beams can be quickly removed by lifting them up and out, making them easy to assemble and disassemble.

|

| Figure 1. An example of two pallet rack drop pins securing the beams into the column. |

Consider the scenario where a beam is accidentally lifted while the level underneath it is loaded or unloaded. Lifting equipment can raise a pallet and its load with enough force to also lift the beam above if hit, something that can be difficult for an operator to notice. Suppose the lifted beam disconnects from the supporting column. In that case, it is then at risk of falling when the lift operator backs away, dropping the supported product and potentially causing damage or injury. Another critical factor is that beams also contribute to the overall capacity by laterally restricting the columns from buckling. Therefore, removing beams–intentionally or not–could unknowingly reduce the load capacity of the rack. It is for this reason that a rack’s load capacity should always be re-evaluated whenever beams are reconfigured.

Pallet racking pins are important because they prevent beams from unclipping from the supporting rack upright when subject to a lifting force from below that may occur in normal warehouse operations.

How Do Safety Pins Work?

Safety pins are installed at the connection between the beam and the column. Every beam is connected to the columns on each end; therefore, two pins must be installed per beam. Each safety pin must be capable of resisting an upward force of at least 1,000 lb (4.5kN) as specified in design codes CSA A344 Section 11.3.1 and ANSI MH16.1 Section 5.4.2.

Steel storage racks using structural steel members with bolt-on beams do not fall under the considerations of these articles. Beams that are securely bolted to the columns do not have the same risk of disconnecting as clip-on beams. For these racking types, it is important to inspect the bolts to verify they are present and properly tightened to the manufacturer’s installation specifications.

How to Prevent Dislodging of Beams

Most commonly, beams are dislodged due to unintentional contact when using lift trucks, both when loading/unloading pallets or by collisions. To reduce the risk of damaging the racking, pallets should only be loaded into cells where a clearance of 6 inches can be maintained between the top of the load and the next beam above it (RMI Considerations for the Planning and Use of Industrial Steel Storage Racks 2.13.2). Additionally, aisles used for circulation should be wide enough for the specific forklift in use, and every equipment manufacturer will recommend a safe aisle width for their rack configurations. For more details regarding aisle width, read this article.

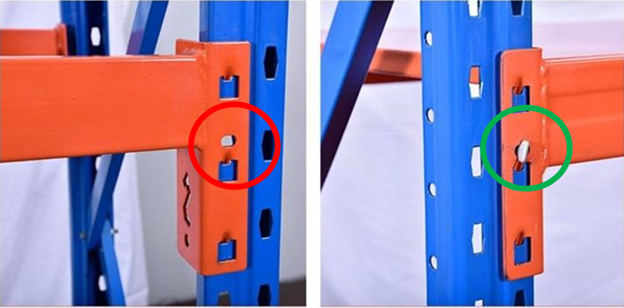

|

| Figure 2. Beam without (left) and with (right) a pallet rack safety pin. (Source: ECO Racking) |

Considering Load Capacity & Pallet Rack Compatibility

While load capacities may exceed 5,000lb per pair of beams, the safety pin requirement remains at 1,000lb each, so 4,000lb per pair of beams. Safety pins are installed only as a preventative device to ensure the beam connector always remains engaged with the column and is never used to support any load or to increase racking capacity. It is important to verify that all beams are properly installed in the columns before installing safety pins and that the safety pins are compatible with the type of racking. An incompatible pin may not be sufficient to prevent the beam from becoming disconnected if it is struck.

Now that the importance of having properly installed safety pins is clear, it should be no surprise that pallet rack drop pins must be installed in all racking systems that are loaded/unloaded using material handling machinery (CSA A344 Section 11.3.1, ANSI MH16.1 Section 5.4.2). On the contrary, the use of safety pins is not required on racking loaded by hand, such as picking levels, where it is less likely that a beam becomes disconnected. That being said, the use of safety pins is always encouraged as an added low-cost protection for workers and where the rack’s use may change to be machine loaded in the future.

Choosing the Right Type of Safety Pin

There are many styles of safety pins available for purchase in case a safety device is not already integrated into the beam connector design. Most can be categorized as either permanent or removable pins. The distinction is that permanent pins are installed with basic tools (wrenches), whereas removable pins require no tools to install or remove. Removable pins offer slightly less protection, as there is nothing, except friction and gravity, preventing the pin from being moved out of the proper position either by vibrations or contact with pallets. This highlights the need for regular rack inspections to ensure the pins are still present and engaged.

Removable racking pins generally have faster installation times and are available at a very low cost; some styles are made by stamping the shape from excess material, leaving behind a drop pin-shaped hole on the beam connector. Seeing a safety pin stamped from the beam clip material is often a hint to the beam manufacturer’s suggested safety pin shape.

Here are a few common safety pin styles:

| Removable J Pin Installed by dropping through aligned holes in the column and beam connector. |

|

| Permanent Bolt Pin Installed by threading through aligned holes in the column and beam connector or secured by a nut on the backside. |

|

| Removable Clip Style Safety Pin Installed by hooking on the beam connector and passing the round pin through aligned holes in the upright column and beam connector. |

|

| Removable Stamped Safety Pin Installed by dropping through aligned holes in the rack column and beam connector. |

|

| Removable Stamped Safety Pin Installed by dropping through aligned holes in the column and beam connector. |

|

When selecting a racking pin style, it is important to consult the rack manufacturer’s recommendations. Some might recommend the use of stamped pins, which have square edges, where others may suggest using round pins. In warehouses where racking is frequently rearranged, there is a small benefit to using removable drop-style pins, where fast and easy installation and removal are desired. However, for warehouses that do not see frequent rack modifications, permanent safety pins such as a nut and bolt are recommended as they are more effective at staying in place and not becoming loose/falling out. Always remember that moving or removing beams can affect the load capacity of your racks, and these changes require updates to the Load Application and Rack Configuration (LARC) drawings.

Add Safety Pins to Your Rack Inspection Checklist

Now that you are more familiar with rack safety pins and their use, be sure to include them on your checklist for your regular warehouse inspections. For a more complete list of what to inspect on your racking, read this article. By paying attention to your pallet rack safety pins and replacing any that are missing or may have been damaged, you can better ensure the safety of all warehouse employees—especially those working near your pallet racks. If ever you are in doubt, contact a rack safety partner for advice.

Frequently Asked Questions: Pallet Rack Safety Pins

What are pallet rack safety pins?

Why are safety pins necessary in pallet racking?

How do pallet rack safety pins work?

Are safety pins required on all types of pallet racking?

Do bolted or structural racks need safety pins?

What causes pallet rack beams to become dislodged?

The most common cause is forklift impact—either directly striking the beam or lifting a pallet into it from below. Other causes include insufficient clearance between the top of a load and the next beam level or operating forklifts in narrow aisles with poor visibility.

To reduce risk:

- Maintain at least 6 inches of vertical clearance above each load (RMI Guidelines 2.13.2).

- Ensure aisles are wide enough for the lift trucks’ turning radius.

- Use safety pins and proper rack protection at all beam levels.

What types of pallet rack safety pins are available?

Common types include:

- Removable J-Pins: Drop through aligned holes in the upright and beam connector.

- Permanent Bolt Pins: Secured with a nut or threaded in place for added durability.

- Removable Clip-Style Pins: Hook onto the beam connector, with a round pin passing through the column.

- Stamped Safety Pins: Made from steel, dropped through holes in the connector and upright.

Each manufacturer may specify a preferred type. Removable pins are convenient for frequently reconfigured racks; permanent pins are ideal for static layouts to prevent accidental removal.

How should safety pins be included in rack inspections?

During inspections, always verify that:

- Each beam has two properly installed safety pins (one on each side).

- Pins are fully engaged and not missing, bent, or loose.

- Pin styles are compatible with the rack manufacturer’s design.

Adding safety pins to your inspection checklist ensures early detection of missing or damaged hardware. Contact a rack safety specialist if pins are absent or incompatible before reloading the affected bays.

Do safety pins increase the load capacity of a rack?

How can Damotech help with pallet rack safety pins and compliance?

Damotech’s rack inspection services and engineering team ensure your racking systems comply with CSA A344, ANSI MH16.1, and RMI standards. Our experts can:

- Verify that all safety pins are installed and compatible.

- Evaluate whether missing pins have impacted load capacity.

- Update your LARC drawings after any rack reconfiguration.

- Provide engineered rack repair solutions after forklift damage.

References:

ECO. Heavy Duty Steel Storage Rack. http://m.ecoindustrialstoragerackings.com/warehouse-storage-racks/heavy-duty-storage-racks/heavy-duty-steel-storage-rack.html

Rack Manufacturers Institute, Inc. (September 30, 2020) How Point Loads and Uniformly Distributed Loads Affect Safe Rack Design . http://www.rmiracksafety.org/2020/09/30/how-point-loads-and-uniformly-distributed-loads-affect-safe-rack-design/

3JC, Ltd.: https://www.3jc.co.uk/identify-your-pins/