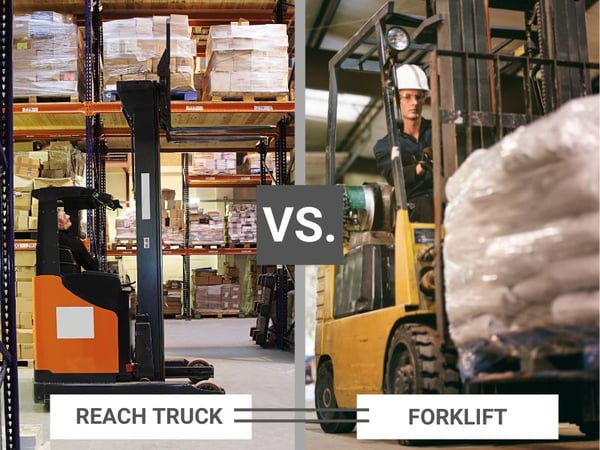

When optimizing warehouse operations, selecting the right equipment is paramount. Reach trucks and forklifts are two common choices, each with unique advantages. While they might appear similar at first glance, they serve different purposes and come equipped with distinct features tailored for specific tasks.

Understanding the difference between these two machines is essential for efficient warehouse functionality and choosing the right tool. This blog will explore the key differences between reach trucks and forklifts, such as their use, benefits, industry applications, and key features, helping you make an informed decision and enhance your warehouse’s efficiency.

Understanding Reach Trucks: The Precision Performers

Reach trucks are versatile machines crucial in effectively handling materials in various industries.

What is a reach truck?

Reach trucks are often referred to as reach forklifts or reach truck forklifts. They are specialized forklifts designed for precise and high-reaching tasks. Unlike traditional forklifts, they have a narrow chassis and are known for their ability to navigate narrow aisles. They feature a design with two outer legs for load distribution and a single set of rear wheels positioned beneath the operator, reducing the turning radius.

Reach trucks are ideal for warehouses with limited space and high-density storage environments, such as warehouses with tall racking systems.

Key features of reach trucks

- Maneuverability: Reach trucks are built for precision, allowing operators to handle tasks in tight spaces.

- Lift height: These machines can reach impressive lift heights, often exceeding those of traditional forklifts, which enables efficient use of vertical storage space.

- Telescoping mast: Reach trucks have a telescoping mast that extends forward to pick up and drop off loads. They feature a forward-extended fork, allowing them to reach deep into storage racks and retrieve or store pallets while maintaining stability.

- Operator seating: Usually, the driver faces sideways, improving visibility when working in confined spaces. Certain reach trucks enable the operator to face forward with an unobstructed view while handling pallets, and face the direction of travel when moving.

- Time efficiency: Reach trucks are known for their speed and efficiency, enabling swift pallet movement and order fulfillment.

- Operator comfort: Designed with operator ergonomics in mind, reach trucks’ cabs provide control for extended periods of use and comfort to reduce fatigue during long shifts.

- Narrow chassis: Reach trucks have a compact design, making them ideal for tight spaces and narrow aisles.

- Advanced control systems: Reach trucks have sophisticated control systems for precision handling.

Various models of reach trucks from left to right: Raymond, Toyota, and Mitsubishi

Various models of reach trucks from left to right: Raymond, Toyota, and Mitsubishi

Benefits of reach trucks

- Space optimization: Reach trucks excel in high-density storage environments. They are designed for high stacking: their excellent stability at height is crucial for safely placing loads on high racks, maximizing vertical storage space.

- Precision handling: Their precise control and maneuverability make them suitable for delicate tasks. These machines offer pinpoint accuracy when positioning and retrieving pallets, reducing the risk of product damage.

- Narrow aisle operation: Reach trucks are built for navigating tight warehouse aisles. These narrow-aisle reach forklifts are well-suited for warehouse environments with limited aisle space where efficient warehouse storage is essential.

Some industries that use reach trucks

- Retail and e-commerce: In fast-paced retail and e-commerce warehouses, reach trucks are critical to meet order fulfillment demands.

- Manufacturing: Manufacturers rely on reach trucks for just-in-time inventory management and efficient material handling.

- Logistics and distribution: In logistics and distribution centers, reach trucks streamline the movement of goods, ensuring timely deliveries.

- Cold storage: Reach trucks are also used in cold storage facilities where precision handling and space optimization are essential.

Understanding Forklifts: Versatile Workhorses for Efficiency, Safety, and Reliability

From manufacturing plants to warehouses, distribution centers to construction sites, forklifts are a common sight.

What is a Forklift?

Forklifts, often called lift trucks, are versatile material-handling machines. They are a staple in warehouses, factories, construction sites, and various industries where heavy lifting and transportation are a daily routine. They come in different types, including counterbalance forklifts, rough terrain forklifts, and warehouse forklifts, offering flexibility for various tasks.

Key features of forklifts

- Counterbalance design: Most forklifts feature a counterbalance design, with the weight of the machine balancing the load.

- Front-facing operator seating: Forklift operators typically sit facing forward, which is beneficial for outdoor and indoor tasks.

- Load capacity: Forklifts vary in load capacity, with some models capable of handling heavy loads, making them suitable for moving pallets of goods, machinery, and large materials.

- Mast configuration: Forklifts may have different mast designs, including duplex, triplex, or quad mast configurations, determining how high the forklift can lift. The forks, or prongs, are attached to the mast and slide under pallets or materials, enabling vertical lifting and lowering.

- Fork types: Forks come in different shapes and sizes to accommodate various load types.

- Power source: Forklifts can be powered by electricity, propane, diesel, or gasoline, each offering advantages.

- Tire types: Tires vary from cushion to pneumatic, suited for different terrains and indoor/outdoor use.

Benefits of forklifts

- Versatility: Forklifts can be used for various tasks, including loading and unloading, transporting, and stacking. They can be equipped with multiple attachments, such as clamps, side shifters, and bucket attachments, to handle a wide range of loads and tasks.

- Load capacity: Some forklifts are built to handle extremely heavy loads.

- Accessibility: Forklifts can handle various tasks in different environments.

- Efficiency: They significantly expedite material handling, reducing labor and time requirements.

- Safety: Forklifts have safety features to protect operators and the materials being handled.

- Cost savings: Their efficiency leads to cost savings in labor and time.

Different models of lift trucks from left to right: Toyota and CAT

Different models of lift trucks from left to right: Toyota and CAT

Some industries that rely on forklifts

- Warehousing and logistics: Forklifts are the backbone of distribution and storage operations. They effortlessly move heavy pallets of goods, helping load and unload trucks and stacking products efficiently.

- Manufacturing: From automotive to electronics, manufacturing relies on forklifts for material handling. They transport raw materials, manage inventory, and assist in assembly processes.

- Construction: In the construction industry, rough terrain forklifts tackle the challenge of uneven ground, assisting with heavy lifting and material transport.

- Agriculture: Forklifts find their place in the farming and agricultural sector, handling large hay bales, machinery, and crop loads.

- Retail: Large retail stores and supermarkets rely on forklifts to handle and transport pallets of goods.

Making the Right Choice: Reach Truck or Forklift—Which Is Best for You?

Before choosing between a reach truck and a forklift for your material handling needs, consider asking yourself the following questions to make an informed decision:

1. What is the primary purpose?

- Are you handling materials in a warehouse, distribution center, or manufacturing facility?

- Do you need to stack items high in narrow spaces, or do you have more room to maneuver?

2. What weight do you need to lift?

- What is the typical weight of the loads you will be handling?

- Do you need to lift heavy loads, or are lighter loads sufficient?

3. Are there space constraints?

- Is your facility limited by narrow aisles or confined areas?

- Do you have enough room to accommodate a forklift’s wider turning radius?

4. How high do you need to stack?

- Will you be stacking items to great heights?

- What is the maximum lift height required for your operations?

5. What attachments will you use?

- Will you need specialized attachments for your material handling tasks?

- Are these attachments compatible with the chosen equipment?

6. What type of tires do you need?

- Will you work indoors or outdoors?

- Do you need cushion tires for indoor use or pneumatic tires for outdoor terrain?

7. What power source is preferred?

- Are you looking for an electric-powered option for emission-free indoor use?

- Do you need a different power source, such as propane or diesel?

8. What is your budget?

- How much can you spend on acquiring and maintaining the equipment?

- Are there any cost constraints that may affect your choice?

9. What level of operator training is available?

- Do you have access to specialized training for reach trucks if needed?

- Are you prepared to invest in operator training for the chosen equipment?

10. What is the expected maintenance cost?

- How much are you willing to spend on ongoing maintenance and repairs?

- Is there a significant difference in maintenance costs between the two options?

11. What are the safety considerations?

- What safety measures and features are essential for your operations?

- Are there industry-specific safety requirements or regulations?

12. What is the versatility requirement?

- Do you need a highly specialized machine for specific tasks?

- Can you benefit from a more versatile piece of equipment that can handle various tasks?

By asking these questions and evaluating your specific material handling needs, you can make a well-informed decision when choosing between a reach truck and a forklift.

Reach Trucks vs. Forklifts— A Comparison Chart

The comparison chart below highlights the main differences between reach trucks and forklifts, emphasizing their unique features and suitable applications. The choice between the two depends on the specific material handling needs of a given operation.

| REACH TRUCK | VS. | FORKLIFT |

| Narrow aisle use, excellent for high stacking in confined spaces | Purpose | Versatile for indoor and outdoor applications, capable of handling heavy loads |

| Typically lower lifting capacity | Lifting Capacity | Generally higher lifting capacity, suitable for heavy loads |

| Triple-stage mast for maximum lift height | Mast Type | Various mast types, including single-stage, two-stage, and three-stage |

| Typically tighter turning radius, ideal for narrow aisles | Turning Radius | Generally wider turning radius, better for outdoor maneuvering |

| Excellent maneuverability in tight spaces for indoor use | Maneuverability | Less maneuverable in narrow aisles but suitable for outdoor applications |

| Limited attachment options due to its specialized design | Attachments | Various attachments, more versatile for different tasks |

| Often in a cabin or stand-on platform with side view | Operator Position | Usually on a seat with front view |

| Extended reach to access deep racks | Reach Distance | Shorter reach but can handle wider loads |

| Cushion tires for indoor use | Tire Types | Cushion or pneumatic tires, for indoor and outdoor use |

| Typically electric-powered for indoor, emission-free use | Power Source | Various power sources, including electric, propane, diesel, and gasoline for versatility |

| Generally more cost-effective for narrow aisle, high stacking applications | Cost | Often a cost-effective choice for general material handling tasks |

| Specialized training required due to the unique operation | Training | Standard forklift training typically applies |

| Lower maintenance costs due to simpler design and indoor use | Maintenance | May have higher maintenance costs due to outdoor use and more moving parts |

| Ideal for warehousing and distribution with high stacking needs | Applications | Versatile for various industries, including manufacturing, construction, and logistics |

Choosing the Right Equipment: Reach Trucks or Forklifts for Your Warehouse Needs

Both reach trucks and forklifts have unique strengths. Your choice between them should align with your specific operational needs, considering factors like space, load size, versatility, budget, and safety considerations. Understanding these differences enables you to make an informed decision, whether you opt for a reach truck for precision or a forklift for versatility.

Nonetheless, it remains paramount to place safety at the forefront, considering that both forklifts and reach trucks, although enjoyable to operate, come with inherent hazards. Daily inspections and maintaining vigilance in the workplace are vital aspects of ensuring a safe and productive warehouse environment.

To improve overall warehouse safety, it is advisable to seek the guidance of experienced safety professionals. Explore how Damotech professionals can assist in identifying the most suitable and adequate safety measures to safeguard your workforce and valuable assets.