Get your safety score and receive recommendations (4 min.)

A damaged rack in your warehouse can significantly impact operations. One incident can cause loss of time, money, productivity - and sometimes, cause serious injury. This is why safety measures should be in place and to maintain the safety of your workers. Want to know where you stand on the topic of rack and warehouse safety? Fill out this free self-assessment questionnaire to find all the answers you are looking for. We'll give you your rack safety score, and give you some quick tips on how to improve!

Rack inspections help ensure that the systems are well-maintained and the safety of workers is not compromised. There is no official rule on the frequency of rack inspections. Industry guidelines recommend the regular inspection of racking systems, and this will depend on the type of activity occurring in your warehouse or distribution center.

Here's what's recommended:

More information on when to inspect.

Pallet rack owners and operators are responsible for displaying the max load capacity of the racking systems, and the labels or plaques should refer to the Load Application and Rack Configuration (LARC) drawings. These documents should always be on-hand as they convey important information about the safe storage capacity of a given rack bay or aisle in the warehouse.

Additionally, we recommend keeping the following:

To display the load capacity of a racking system you can use adhesive labels placed on the first beam elevation, at eye level. If your racks have the same load capacity throughout, you can use rated load plaques to remind the forklift operators of the load capacity before entering an aisle. These plaques generally include the maximum bay capacity, maximum beam capacity, and the details about the rack's manufacturer with a project date.

When you notice a damaged rack, the safest thing to do it to report it and document the damage, with pictures and a date, this way, you can track the issue. Then, you can unload that part of the rack until it is repaired or replaced.

Talk to an expert to get a free assessment.

Rack load capacity should be re-evaluated when there have been modifications made to the rack or if you cannot find the rated load capacity supplied by the rack manufacturer. Damotech's engineers offer load capacity calculation services for any type of pallet racking system.

Rack owners and warehouse operators must ensure that rack aisles are free of any pallets or obstructions on the floor to allow for lift trucks to be driven safely and for merchandise to be loaded and unloaded into the racks in the safest manner. We call this good housekeeping!

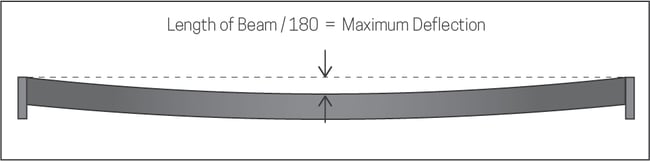

We've written a full article on everything there is to know about beam deflection!

When heavy loads are applied to beams, the beams may begin to sag. This is also called a deflection, which is the degree to which a structural element is displaced under a load. The deflection of beams is permitted but only to a certain limit: Horizontal length of the beam (L) / 180 = Maximum deflection.

This is stated in Section 5.3 of RMI’s ANSI MH16.1-2012: Specification for the Design, Testing and Utilization of Industrial Steel Storage Racks.

Traditionally, warehouse rack inspections have been recorded on paper, but today, you can track issues digitally, to simplify the process and facilitate the reporting of issues or rack deficiencies.

For example, by using technology like our platform, you can take a picture of the damage, label it with a priority and report it immediately. When you manage your inspections digitally, it greatly facilitates the sorting of issues found, and it keeps a history of your past inspections, all in one place!

Field welding or welding a reinforcement on existing racks may seem like a simple and inexpensive way of repairing a damaged rack, but this option poses a risk to the safety of your system.

Since it's difficult to test the result of the weld and guarantee a resistance at least equal to that offered by the original rack component, there are strong recommendations against field welding in a warehouse on existing pallet racking.

This is outlined in Appendix 1 of RMI’s “Guideline for the Assessment and Repair or Replacement of Damaged Rack"

You can try a bolted solution instead.

Protecting your pallet rack uprights will safeguard them against damage caused by forklifts and extend the life of your storage systems. It will also make your warehouse much safer!

You can start by adding rack guard or protection in high traffic areas or on parts of the rack that are more prone to accidents, such as the end of aisles or the shipping and receiving area of a warehouse.

You can also protect other parts of your warehouse, such as building columns or pedestrian walkways, with heavy-duty guarding solutions.

The building columns in your warehouse should be protected as damage to these structural load-bearing elements are costly to fix and pose a risk to the structural integrity of the building.

The Damo Shield is a 360-degree column protector that can be tailored to the shape of your columns, to protect them from all impacts, especially the nasty ones caused by forklifts and their blades.

Any other building elements or valuable equipment can be protected with our custom fences or guardrails.

The risk of products or pallets falling from a rack can be minimized with the use of fall protection accessories. A wide range of products can protect your warehouse aisles from falling objects or merchandise:

These accessories are common, relatively inexpensive, and will increase the level of safety in a warehouse. Did you know that Damotech is part of ProGMA, the Protective Guarding Manufacturers Association? Members are the Industry’s leading suppliers of fixed protective guarding products designed to protect personnel, equipment, and inventory in industrial facilities.

Several things can be done to protect workers and pedestrians in a warehouse environment:

Anyone working near racks or within a warehouse can benefit from extra pallet rack safety training. This includes senior management and supervisors in health and safety, operations, risk management, and maintenance, all the way to the forklift operators. Some of the benefits of rack safety training are:

Rack aisles need to be wide enough to allow the safe circulation and maneuvering of forklifts. To find out what space is required in your aisles with the equipment you are using, use a formula or refer to the forklift manufacturer’s recommendations. At a minimum, the width should be equal to the width of the loaded forklift, plus 12 inches. Read more

To assess the level of safety of your racking systems, schedule a conformity inspection performed by an experienced engineer or rack specialist. This thorough inspection will result in a stamped report. Use the findings to flag issues and track them, either by using a spreadsheet or by reviewing the results of the inspection in Damotech's rack inspection management platform.

It largely depends on the nature of the work performed by the employees in the warehouse. Because their job involves working in a hazardous environment, workers will be required to wear various equipment that protects them from hazards. Some common Personal Protective Equipment (PPE):

With few exceptions, OSHA requires employers to provide personal protective equipment used to comply with OSHA standards. The standard makes clear that employers cannot require workers to provide their own PPE. Employers are also responsible for making sure that PPE requirements are being followed in the workplace.

A warehouse's safety involves everyone that works in it. It starts with a management plan that includes ongoing training, regular safety meetings, implementation of prevention measures, and safety strategies. Employers must oversee employees in safe practices and procedures. Concerning accountability, they must take reasonable measures to require employee compliance. In other words, while employers are responsible for providing a safe workplace, workers are responsible for respecting safety measures and having safe behavior at work.