As a warehouse manager or operator, ensuring the safety and reliability of your racking system is of utmost importance. Regular visual inspections are vital for identifying and addressing any damage or weaknesses in the pallet racks. However, with knowledge of the specific terms for each rack component, it can be easier to communicate effectively and take action to rectify issues.

In this blog, we will delve into the main components of a racking system and provide quick tips on what to look for during inspections. By familiarizing yourself with these terms, you’ll be better equipped to address any damage promptly, reduce the risk of accidents, and ensure your warehouse meets regulatory compliance. Explore the essential components of maintaining a safe and efficient warehouse environment.

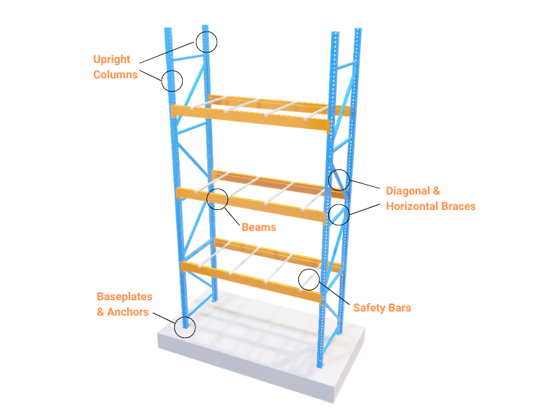

Pallet Rack Uprights

The upright frame consists of columns, i.e., the two vertical components where the braces are welded. During inspections, examining the front and rear columns is crucial. For instance, twisted columns can significantly diminish the rack’s load capacity, representing the maximum weight it can safely bear.

Neglecting such damages could result in a collapse of the racking system, underscoring the importance of promptly addressing significant column damage to ensure its safety.

Figure 1: Damaged Upright.

Pay attention to the following issues during your inspection:

- Check if the columns are straight.

- Look for any evidence of impact.

- Examine whether the columns are twisted.

- Check for rust on the columns.

- Ensure the welds are intact.

Tip: At both extremities of a rack system, your upright column should always exceed the height of the highest beam. It prevents packages from falling onto a pedestrian pathway, especially in high seismic zones.

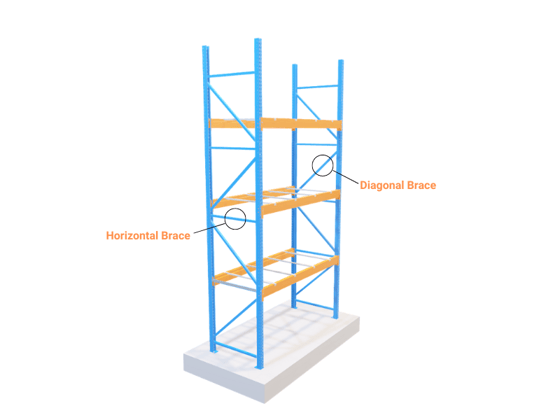

Braces for Rack Stability

Braces are diagonal or horizontal members bolted or welded between frame columns in a specific pattern, creating an upright structure. Their purpose is to counter cross-aisle forces exerted on the rack’s frames and enhance the overall stability of the racking system.

Check all the horizontal and diagonal braces:

- Are any braces missing?

- Do you notice any dents or deflections?

- Are the braces adequately attached (i.e., are the welds intact)?

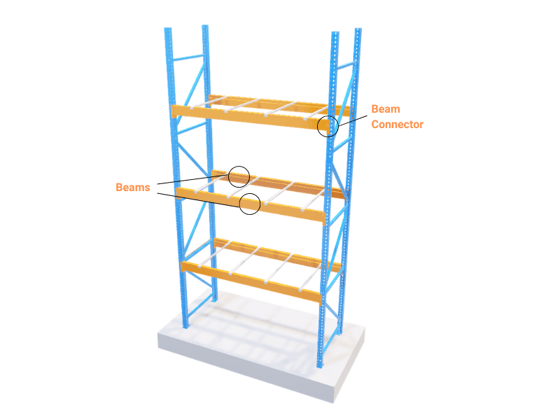

Beams and Pallets

Beams serve as the horizontal structural elements in a pallet racking system. Their primary role is to bear the weight of stored loads, typically pallets, and transfer this weight to the columns to which they are securely connected. While rack beams can support heavy loads, their capacity is not unlimited.

Figure 2: Beam Deflection.

When assessing beam and pallet positioning, the following issues should be looked at:

- Are the beams straight with no deflection when unloaded?

- Are the beam connectors securely attached to the column?

- Are safety pins in place?

- Are bolts adequately torqued?

- Do the beams appear overloaded?

- Are the pallets intact and suitable for use, with none missing?

Damaged racks in your warehouse? Book a FREE on-site assessment now.

It’s crucial to ensure that the pallets are in proper condition. What factors should be considered when it comes to damaged pallets? Numerous things could go wrong, such as cracks, glass, odor, contamination, outdated labels, protruding nails, and overloading. If a fully loaded pallet is damaged, it’s difficult to determine whether it broke during the loading process or was already broken. Nonetheless, all staff members should ensure that the pallets they work with are in good condition.

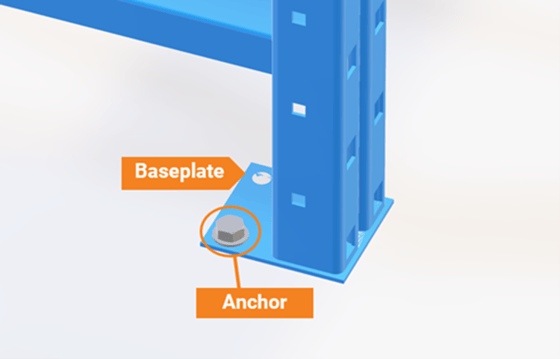

Anchors and Baseplates

Baseplates, or footplates, are welded to the bottom of a racking column or repair unit to distribute the weight of the racking system on the ground. Additionally, they facilitate secure anchoring of the system using anchor bolts.

Anchors, or anchor bolts, ensure the pallet rack system remains securely positioned by fastening it to the building floor. Despite their small size, pallet rack anchors for column bases are critical.

Per industry standards, at least one anchor per baseplate must anchor the racking system to the floor. This configuration enhances the racking system’s ability to withstand forces such as earthquakes, wind, overturning, shear forces, or accidental impacts on the lower ends of the columns.

Figure 3: Damaged Baseplate.

When you walk the facility and evaluate the anchoring system, the following issues should be reviewed:

- Are any anchors missing?

- Are the anchor bolts damaged, loose, or bent?

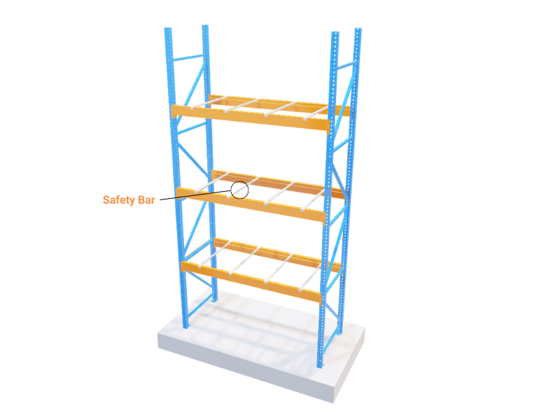

Safety Bars

Safety bars are supported by pallet racks’ front and rear beams, designed to support misplaced pallets temporarily. Although not mandatory, they are highly recommended to prevent pallets from falling between beams. These bars can help prevent accidents that could cause severe employee injuries and damage to goods or storage systems.

Be sure to focus on the following aspects during your inspection:

- Are safety bars in place and secured to the beams?

- Are they positioned at the first and third quarters of pallet width?

- Are the safety bars preventing pallets from falling through?

- Are there two safety bars per pallet position?

Rack Safety Add-Ons

Relying solely on standard pallet rack components may not be enough. Consider additional rack safety components to bolster your rack safety measures. Let’s explore some essential rack safety add-ons that can elevate your safety standards and contribute to a safer work environment.

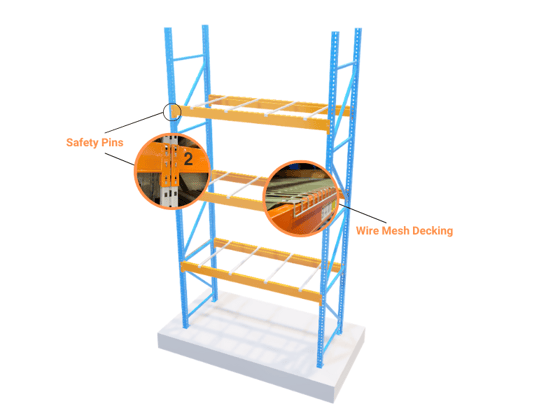

Safety Pins for Pallet Racks

Safety pins, also known as connection locking devices, locking clips, or bolts, are small yet crucial devices designed to prevent beams from dislodging in pallet racks. Their primary purpose is to secure the pallet rack beams to the uprights, ensuring they stay connected even when exposed to upward forces caused by pallet loads or forklift impacts.

As per RMI’s ANSI MH16.1-2012, safety pins are commonly included as a standard component by the racking system’s manufacturer and recommended as a safety practice. Safety pins are installed at the connection point between the beam and the column. Since each beam is supported on both ends, it’s essential to have two pins installed per beam to ensure maximum stability and safety in the pallet rack system.

Wire mesh decks

Wire mesh decking is installed on pallet rack shelves. It serves as an extension of safety bars, providing a reliable solution to prevent pallets, products, and debris from slipping through the gaps between beams.

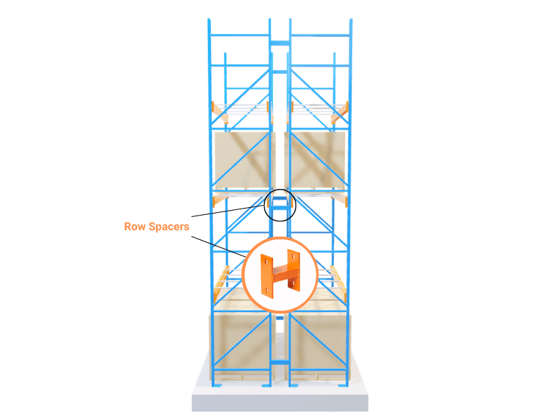

Row spacers

Load-carrying members are designed to stabilize two rows of upright frames, ensuring the rack system functions at its intended load capacity. These components serve as spacers for back-to-back pallet racks, maintaining consistent spacing between the racks. They should be positioned at elevations that create a direct load path between the columns of the back-to-back frames.

During your inspection, make sure to review the following issues:

- Are any of the previously mentioned items in place and properly secured?

- Are any missing?

Warehouse Rack Safety Standards: OSHA, ANSI, SEMA, and Inspection Checklists

Several well-established standards and regulatory expectations guide warehouse racking safety. While OSHA does not publish a rack-specific standard, it enforces racking safety through broader material-handling regulations and the General Duty Clause. Additionally, ANSI/RMI and international guidelines provide detailed best practices for storage rack design, inspection, and maintenance.

Key Regulatory & Industry Standards

1. OSHA (Occupational Safety and Health Administration – USA)

While not rack-specific, several OSHA regulations apply directly to racking systems:

- General Duty Clause (Section 5(a)(1)) — Employers must keep workplaces free from recognized hazards, which include unsafe or damaged racking.

- 29 CFR 1910.176 (Material Storage) — Requires safe clearances, secure stacking, and hazard-free storage areas.

- 29 CFR 1910.22 (Housekeeping) — Walkways and storage areas must remain clean and orderly.

- 29 CFR 1910.178 (Powered Industrial Trucks) — Operator behavior, load handling, and forklift impacts all directly affect rack safety.

OSHA commonly references ANSI MH16.1 during inspections to determine whether a facility has followed recognized best practices.

2. ANSI / RMI MH16.1 (North America)

The Rack Manufacturers Institute (RMI) publishes ANSI MH16.1, the most widely respected standard governing the design, testing, utilization, and maintenance of pallet racks.

It covers:

- load capacities

- beam and frame design

- anchoring requirements

- allowable deflection

- seismic considerations

- required safety components such as safety pins

- manufacturer responsibilities

While voluntary, failure to meet it is often considered failure to control a recognized hazard.

3. BS EN 15635 (UK / EU)

This standard provides detailed guidance for:

- inspection routines (daily, weekly, annual expert inspections)

- damage classification

- repair procedures

- documentation requirements

Many companies use it as a benchmark even outside Europe because of its clarity and practical framework.

4. SEMA (Storage Equipment Manufacturers Association – UK)

SEMA guidance includes:

- safe installation standards

- repair expectations

- load sign requirements

- the SEMA Approved Racking Inspector (SARI) program

Although these guidelines are international, they closely align with North American expectations and shape global best practices.

Common Elements of Rack Safety Checklists

Most professional inspection checklists include:

Category |

What to Check |

|

Rack Structure |

Uprights, beams, frames, braces for dents, twists, rust, misalignment, and missing components |

|

Connections & Fasteners |

Welds, bolts, beam connectors, safety clips/pins, and locking devices |

|

Anchors & Baseplates |

Presence, tightness, damage, bending, or missing anchors |

|

Load Capacity Signage |

Correct load signs are visible and match the actual configuration. |

|

Pallet Condition |

Cracked pallets, missing boards, contamination, and protruding nails |

|

Rack Alignment & Verticality |

Plumbness, beam deflection, spacing, and row spacers |

|

Environmental Conditions |

Corrosion, moisture, temperature impacts, and lighting |

|

Aisle Conditions |

Adequate clearances and obstruction-free pathways |

|

Documentation |

Up-to-date LARCs, inspection history, and repair records |

|

Inspection Frequency |

Weekly/monthly internal checks + annual expert inspection |

These elements align with best-in-class audit templates used in the material handling industry.

Best Practices for Using Standards & Checklists

1. Start with the applicable standards — ANSI MH16.1 for North America, plus internal policies.

2. Conduct regular in-house inspections using structured checklists.

3. Perform annual third-party engineering inspections to stay compliant and maintain safety levels.

4. Train employees to recognize racking hazards and report damage.

5. Document everything — findings, repairs, reconfigurations, and load capacity changes.

Additional Factors to Consider During Warehouse Rack Inspections

Do your rack inspections cover all aspects and remain current? Below are additional factors to consider concerning the safety of your warehouse racks:

- Documentation: Do you possess updated rack load capacity and configuration drawings or plans for your warehouse racking systems?

- Employee Training: Are employees adequately trained to recognize rack safety hazards and issues? Is there a procedure for reporting damage?

- Visual Inspections: Do regular visual inspections of the pallet racking systems occur in your warehouse?

- Aisle Conditions: Are the aisles between your racking systems clear and free from obstruction or clutter, with adequate lighting and space for forklift operators to maneuver?

- Rack Safety Program: Have you established a comprehensive rack safety program encompassing your warehouse’s rack maintenance and inspection procedures?

- Installation Compliance: Are the racks installed according to the drawings and specifications provided by the rack manufacturer or an engineer?

- Load Capacity Visibility: Are your pallet racks’ maximum rated load capacity visible to operators on labels or plaques?

- Flooring Condition: How is the condition of your flooring or concrete slab? Have you noticed any cracks near the base plates of the racks?

- Rust and Corrosion: Do you see any signs of corrosion or rust on the pallet racks, especially hidden areas like behind guards or at the base?

- Prevention Accessories: Do you use protection accessories such as nets, screens, or wire mesh decking to prevent objects from falling into walkways where pedestrians circulate?

- Protective Measures: Have you installed protective guards on the racks in high-traffic areas or at the end of the aisles?

In summary, rack inspections can sometimes be challenging, especially for those needing more time, resources, or expertise. That’s why teaming up with a rack safety expert is so beneficial. By partnering with these professionals, you can focus on your business while they take care of rack safety. Whether you need advice on safety practices, help with maintenance, or support in an incident, these experts are here to ensure your warehouse runs safely and efficiently.

FAQ: Warehouse Rack Inspection & Safety

How often should pallet racks be inspected?

Who is qualified to perform a rack inspection?

What are the most common signs of rack damage to watch for?

Warehouse teams should look for:

- dents, twists, or buckling in uprights

- missing or bent braces

- beam deflection or unsecured connectors

- missing safety pins or locking devices

- loose, damaged, or missing anchors

- rust or corrosion at the base

- damaged or unstable pallets

Any of these can reduce load capacity and increase the risk of system failure.

Does OSHA have specific regulations for pallet racks?

OSHA does not publish a rack-specific standard, but several regulations apply:

- General Duty Clause (Section 5(a)(1))

- 29 CFR 1910.176 – material handling and safe clearances

- 29 CFR 1910.22 – housekeeping

- 29 CFR 1910.178 – forklift operation around racking

During inspections, OSHA frequently references ANSI MH16.1 as the recognized engineering standard for rack design and usage.

What industry standards should my warehouse follow for rack safety?

The primary guidelines include:

- ANSI MH16.1 (RMI) – U.S./Canada standard for rack design, deflection limits, anchoring, and use

- BS EN 15635 – EU standard for inspection frequency and damage classification

- SEMA guidelines – installation, repair practices, and load signage

These standards help ensure racks remain structurally sound and compliant with regulatory expectations.

What should a pallet rack inspection checklist include?

A complete checklist typically covers:

- uprights, beams, braces, and safety components

- anchor bolts and baseplates

- pallet condition

- load capacity signage

- alignment, plumbness, and beam deflection

- aisle conditions and forklift clearances

- rust, corrosion, or environmental issues

- documentation and repair history

Using a structured checklist reduces the risk of missed hazards.

If rack damage is found, should I repair or replace the affected component?

Are safety bars or wire mesh decking required?

While not always mandatory, both are strongly recommended.

- Safety bars prevent pallets from falling between beams.

- Wire mesh decking adds a layer of protection against falling objects, particularly above pedestrian walkways or rack tunnels.

Many warehouses adopt them proactively to meet internal safety standards and reduce incident risk.

How do I know if my rack’s load capacity is correct?

What documentation should I maintain for compliance?

You should keep:

- recent inspection reports

- LARCs and load capacity calculations

- repair and modification records

- employee rack safety training logs

Digital tools make this easier and help demonstrate due diligence during OSHA audits.

How do I reduce the risk of rack collapses in my warehouse?

Key preventive actions include:

- conducting routine inspections

- keeping aisles clear and well-lit

- ensuring operators receive proper forklift training

- replacing damaged pallets

- anchoring all racks correctly

- installing protective devices in high-traffic areas

Preventive maintenance is significantly more cost-effective than dealing with a collapse.

Can software help manage rack inspections and maintenance?